INPHIC Fully Automatic Large Granule Horizontal Flow Conveyor Packaging Machine

The INPHIC Fully Automatic Large Granule Horizontal Flow Conveyor Packaging Machine is a high-efficiency automated solution tailored for large granule food packaging. Designed specifically for the food industry, it meets the demands of high efficiency and stability. With a 450mm film width and a packaging speed of 40-200 packs per minute, this machine is ideal for large granule foods such as instant noodles, bread, fruits, fresh vegetables, biscuits, and convenience foods. It ensures tight sealing, product integrity, and enhanced visual appeal to help food enterprises improve their market competitiveness.

The compact design integrates a stable conveyor system and high-precision sealing technology, supporting various packaging materials and bag sizes. This machine has been widely adopted by leading Taiwanese food brands and is the ideal solution for improving product quality and production efficiency.

Product Features and Advantages

-

Specialized Design for Large Granule Foods

- Supports the packaging of large granule foods such as nuts, biscuits, instant noodle blocks, bread, fruits, fresh vegetables, dried fruits, and snack bars, offering a stable and efficient packaging solution.

-

Flexible Bag Size Options

- Wide bag size range (length: 130-360mm, width: 50-260mm) to accommodate diverse product requirements, particularly for larger packaging needs.

-

High-Speed Production Efficiency

- Packaging speeds of up to 40-200 packs per minute, meeting the demands of large-scale production lines and boosting operational efficiency.

-

Stable Conveying and Sealing

- Equipped with a precise conveyor belt and sealing system to ensure a smooth packaging process, neat bag shapes, and tight sealing, preserving product integrity and freshness.

-

Compatible with Multiple Packaging Materials

- Supports various packaging films, including composite films and aluminum foil, meeting the food industry's stringent packaging standards.

-

Compact Design and Low Energy Consumption

- Machine dimensions: 4200 x 1250 x 1750mm, power consumption: 3kW. Its compact structure saves space and energy, adapting to diverse factory layouts.

-

Trusted by the Food Industry

- Successfully adopted by multiple Taiwanese food brands to package nuts, snacks, and convenience foods, showcasing exceptional stability and efficiency.

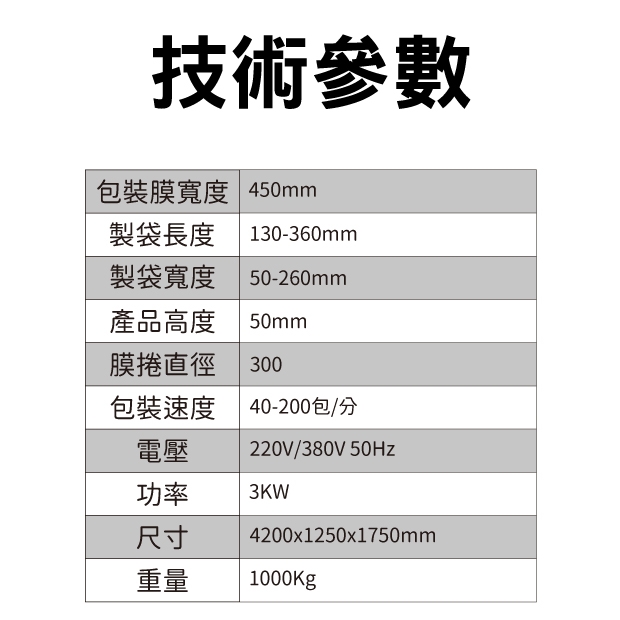

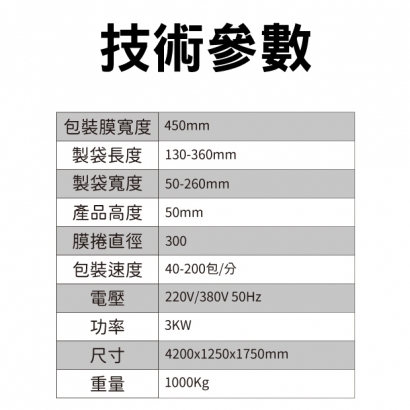

Technical Specifications

- Film Width: 450mm

- Bag Length: 130-360mm

- Bag Width: 50-260mm

- Product Height: 50mm

- Film Roll Diameter: 300mm

- Packaging Speed: 40-200 packs/minute

- Voltage: 220V/380V, 50Hz

- Power: 3kW

- Dimensions: 4200 x 1250 x 1750mm

- Weight: 1000kg

Industry Applications

-

Nuts and Dried Fruits

- Perfect for packaging pistachios, almonds, walnuts, raisins, and similar products with excellent sealing performance to extend shelf life.

-

Biscuits and Snack Bars

- Suitable for packaging biscuits, chocolate bars, and granola bars, ensuring visually appealing and tightly sealed packaging to enhance market appeal.

-

Convenience Foods

- Ideal for instant noodle blocks, soup packs, and other convenience foods, supporting large-scale production to meet the fast-moving consumer goods market.

-

Health and Functional Foods

- Designed for dietary fiber bars, protein bars, and nutritional meal replacements, providing precise packaging to elevate brand image.

Packaging Highlights and Market Advantages

- Specialized for Large Granule Foods: Ideal for steamed buns, bread, biscuits, and convenience foods, ensuring product integrity and visual appeal.

- High Efficiency and Stability: Supports high-speed production with consistent bag shapes, enhancing product market competitiveness.

- Flexible Adaptability: Compatible with various bag sizes and packaging materials to meet diverse market needs.

- Trusted by Leading Food Brands: Widely adopted by top Taiwanese food brands, demonstrating exceptional performance and reliability to help enterprises create a high-quality product image.

Contact INPHIC Today to Discover the Potential of Flow Conveyor Packaging Machines and Stand Out in the Market!

The INPHIC Fully Automatic Large Granule Horizontal Flow Conveyor Packaging Machine is the ideal solution for the food packaging industry. Perfect for nut packaging, snack packaging, instant noodle packaging, and functional food packaging, this machine combines stable performance and high-efficiency design to help enterprises improve production efficiency and product quality.