INPHIC Granular Powder Weighing and Dosing Bag Packaging Machine

The INPHIC Granular Powder Weighing and Dosing Bag Packaging Machine is a highly efficient automated packaging equipment designed specifically for the food, pharmaceutical, chemical, and cosmetic industries. This machine integrates precise weighing technology with advanced bag packaging design, providing professional packaging solutions for diverse products. It helps enterprises improve production efficiency and reduce manual labor.

Product Features and Professional Advantages

-

Wide Industry Applicability

This equipment perfectly addresses the packaging needs of granular, solid, and puffed materials in the food, pharmaceutical, chemical, and cosmetic industries. It provides stable packaging performance for a variety of products, including seasoning, drug granules, and health foods. -

Diverse Packaging Forms

It supports multiple pre-made bag types such as self-sealing bags, stand-up pouches, and zipper pouches. Packaging options are flexible and aesthetic, with different dosing structures available depending on material characteristics, and optional batch printing functions to meet market diversity. -

Fully Automated Intelligent Operation

Equipped with a touch screen and PLC control system, the packaging process is fully automated, requiring no manual intervention. It includes automatic compensation technology for sealing temperature, ensuring stable and precise sealing that enhances both aesthetics and quality. -

High Compatibility with Packaging Materials

It supports various pre-made bag materials such as PE composite film, pure aluminum, and aluminum-coated bags, adapting to diverse market demands and providing excellent sealing and moisture-proof effects for products. -

Stable and Efficient Production Capacity

It offers a stable packaging speed of 20-35 bags per minute, with a weighing range of 20-500g, and is adaptable to bag lengths from 100-260mm and bag widths from 120-180mm, catering to different product specifications. -

Energy-Efficient and Environmentally Friendly Design

The design minimizes energy consumption and uses high-efficiency air supply (>0.6 Mpa), reducing resource waste and helping enterprises achieve green production goals.

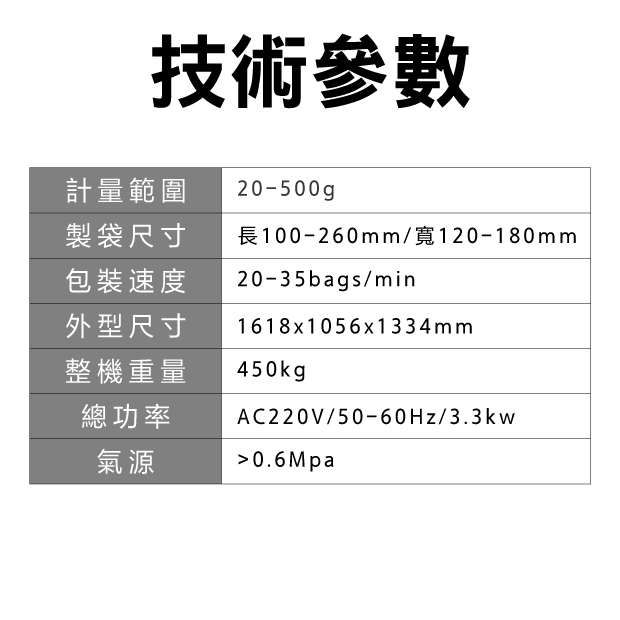

Technical Parameters

- Weighing Range: 20-500g

- Pre-made Bag Size: Length 100-260mm, Width 120-180mm

- Packaging Speed: 20-35 bags/minute

- Dimensions: 1618×1056×1334mm (customizable specifications)

- Machine Weight: 450kg

- Power Supply: AC220V, 50-60Hz, 3.3kW

- Air Supply Requirement: >0.6 Mpa

Application Scenarios and Specialized Relationships in the Food Industry

The INPHIC Granular Powder Weighing and Dosing Bag Packaging Machine is widely used in the following food packaging scenarios:

- Food Processing: Such as coffee powder, milk powder, mixed grains, seasoning, etc.

- Puffed Foods: Such as snacks.

- Health Foods: Such as protein powder, dietary fiber, and other functional foods.

For the food industry, this equipment can precisely control the weight of each bag to ensure consistency. The efficient sealing technology provides long-term storage protection for food products, enhancing product competitiveness and market acceptance.

Contact INPHIC Now to Upgrade Your Food Packaging Line, Explore High-Efficiency Applications of Granular Powder Weighing and Dosing Packaging Machines, and Make Your Products Stand Out in the Market!

The INPHIC Granular Powder Weighing and Dosing Bag Packaging Machine is a top-tier food packaging machine, specifically designed for food powder packaging machines and granular packaging machine needs. It combines precise weighing, efficient dosing, and aesthetic packaging characteristics. This equipment not only improves production efficiency but also achieves high-quality, high-stability packaging solutions in the food industry, making it an ideal choice for food processing plants.