INPHIC Granule Bag Packaging Machine with Ten Stations

INPHIC Granule Bag Packaging Machine with Ten Stations is a high-efficiency, fully automatic packaging equipment designed for granulated food products. It features advanced vacuum packaging technology and an intelligent control system specifically serving the food, pharmaceutical, and chemical industries. This machine demonstrates excellent packaging efficiency and high-quality assurance in the food industry, whether for large food factories or small production lines. It provides an ideal packaging solution, meeting the demand for high performance, stability, and long-term preservation.

INPHIC Granule Bag Packaging Machine with Ten Stations also excels in enhancing packaging efficiency while precisely controlling each bag's seal and vacuum level, ensuring that granulated food remains unaffected by external environments during transport and storage, maintaining its original flavor and nutritional value to the maximum extent. This advantage is especially suited for food industries requiring high preservation and long-lasting storage.

Additionally, the machine’s high-efficiency operation and intelligent design have been highly praised by many well-known food companies in Taiwan, particularly in improving production line efficiency and reducing labor costs. These companies’ high evaluations of the equipment's stability, ease of operation, and packaging quality have established INPHIC Granule Bag Packaging Machine as a trusted choice in the industry, providing a solid foundation for many food companies' product quality and market competitiveness.

Product Features and Advantages

-

Ten-Station Intelligent Design

- The machine is divided into 8 stations for bagging and 10 stations for vacuuming, performing automatic bagging, filling, vacuuming, and sealing processes throughout, significantly improving production efficiency.

-

Smart Operation and Control

- Equipped with a programmable logic controller (PLC) and a large touch screen interface, operations are simple and intuitive. It supports automated control of movements, ensuring high-precision actions and real-time data monitoring.

-

Empty Bag Detection and Material Saving

- Includes an empty bag detection device, which automatically stops sealing if a bag is not opened or not filled, preventing material wastage and reducing production costs.

-

Advanced Sealing Technology

- Utilizes instant heating and water cooling sealing methods, ensuring even and visually appealing seals that are compatible with different types of packaging materials, ensuring package sealing and product quality.

-

Servo Control System

- Features a fully servo-controlled motion system, ensuring precise, fast, and reliable actions that meet high-efficiency production demands.

-

Complies with International Standards

- The equipment is designed to comply with GMP standards and is CE certified, meeting domestic and international market demands, suitable for export use.

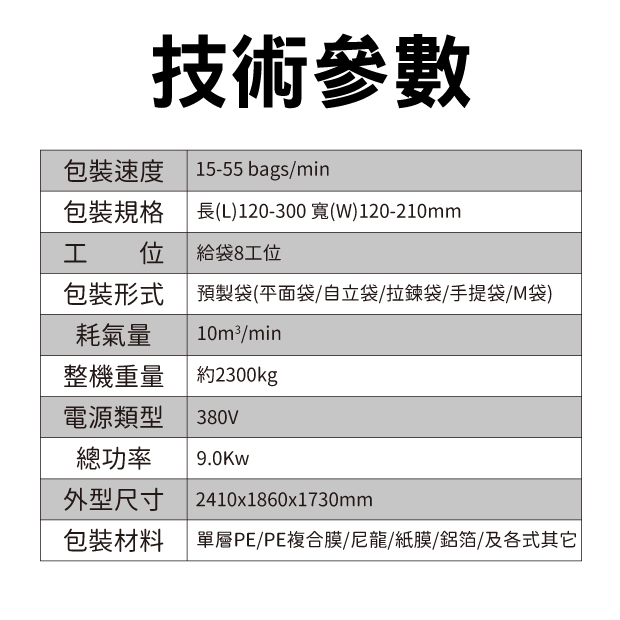

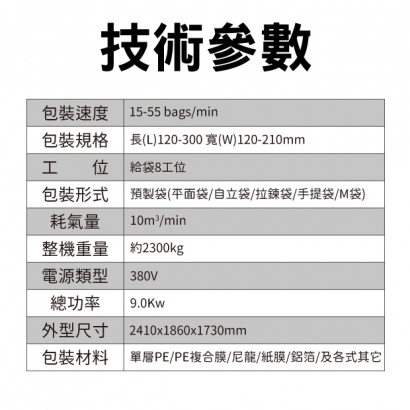

Technical Specifications

- Packaging Speed: 15-55 bags/minute

- Packaging Specifications: Length (L) 120-300mm, Width (W) 120-210mm

- Gas Consumption: 1.0 m³/min

- Number of Stations: 8 for bagging, 10 for vacuuming

- Machine Weight: Approximately 2300kg

- Power Supply: 380V, Total power 9kW

- Dimensions: 2410×1860×1730mm

- Packaging Materials: Single-layer PE, PE composite film, nylon, aluminum foil, paper film, and other materials

Application Scenarios

INPHIC Granule Bag Packaging Machine with Ten Stations is widely used in:

-

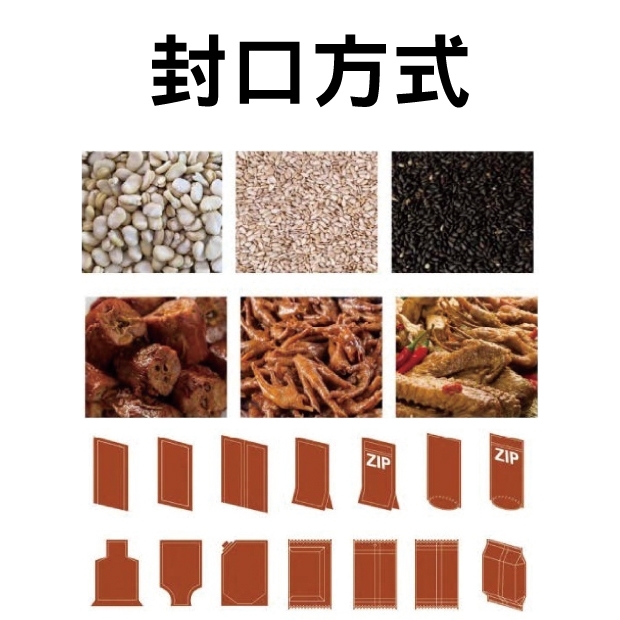

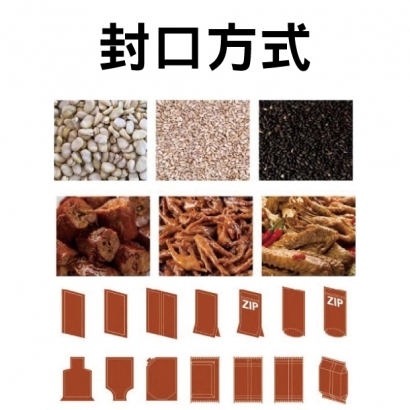

Food Industry

- Suitable for vacuum packaging of rice grains, beans, cereals, dried fruits, coffee beans, biscuits, candies, jerky, squid strips, seaweed, and other granulated products, providing high-quality sealing, extending the product's shelf life, and enhancing the product’s value.

-

Pharmaceutical Industry

- Packages herbal granules and health granules, ensuring hygiene standards and product stability.

-

Chemical Industry

- Used for packaging chemical raw materials, ensuring moisture and oxidation resistance, suitable for long-term storage requirements.

-

Other Industries

- Applicable for pet foods and specialty granulated products, meeting the demand for high-quality vacuum packaging in the market.

Food Processing Packaging Applications

- Dried Fruit: Almonds, cashews, raisins, etc., are vacuum-packed to effectively prevent moisture and oxidation, extend storage time, and maintain the freshness of dried fruits.

- Grain Products: Rice, glutinous rice, oatmeal, etc., are packaged in a precise manner to ensure the grains are not contaminated and prevent moisture and pests.

- Seasonings: Salt, sugar, pepper, etc., are vacuum-packed to prevent moisture clumping and maintain their flavor for a long time.

- Ready-to-eat Foods: Instant noodles, curry packs, etc., can retain their flavor and nutritional content even during storage.

- Tea Leaves and Coffee Beans: Tea leaves, coffee beans, etc., require maintaining their aroma, and vacuum packaging effectively blocks oxygen, extending their freshness.

- Pet Food: Dog food, cat food, etc., packaging machines ensure food freshness, prevent moisture and spoilage, and protect nutritional components.

Contact INPHIC now to learn more about packaging machine solutions, and elevate both your production efficiency and product quality!

INPHIC Granule Bag Packaging Machine is the top choice for granulated food packaging machines, specifically designed for food vacuum packaging machines, combining intelligent control with stable performance to provide businesses with a high-efficiency and stable production experience. The equipment supports multiple bag types and materials, suitable for various industry applications, particularly in vacuum packaging machine needs for food packaging, enhancing product storage safety and market competitiveness.