INPHIC Powder Ten-Station Rotary Belt Bagging Machine

INPHIC Powder Ten-Station Rotary Belt Bagging Machine is a high-efficiency, intelligent automatic packaging equipment designed for the automated packaging needs of powdered products. Its ten-station structure and full-servo control system provide outstanding stability and efficiency, making it suitable for a variety of powdered products across the food, pharmaceutical, chemical, and other industries, especially those requiring high productivity and precision.

The automated control system not only offers stable operation and high packaging speed but can also be adjusted according to the characteristics of different powdered products, achieving precise packaging effects. Its intelligent design can automatically adjust packaging sizes to fit different bag types and specifications without manual intervention, significantly reducing operational costs and error rates.

INPHIC's Powder Ten-Station Rotary Belt Bagging Machine has been highly recognized by many renowned Taiwanese food companies. These companies have given positive feedback on the equipment's performance in enhancing production efficiency, ensuring product quality, and reducing costs. Whether for large-scale production or small batch customization, the INPHIC machine provides a stable and reliable packaging solution, helping businesses stand out in a competitive market and enhancing brand value.

Product Features and Advantages

-

Ten-Station Efficient Design

- Adopts a ten-station rotary structure, achieving fully automated operations from bag feeding, opening, filling, to sealing.

- Supports a packaging speed of up to 100 cans per minute, meeting medium to large batch production requirements.

-

Intelligent Operation and Control

- Controlled by an industrial computer (based on EtherCAT bus) and a large touch screen interface, the operation is simple and intuitive, with easy data adjustments.

- Equipped with an automatic fault tracking and alarm system, displaying real-time operation status and quickly locating and resolving issues, enhancing production stability.

-

Empty Bag Detection and Packaging Material Savings

- Features an empty bag detection device; if an unopen bag or no fill is detected, the system halts sealing, preventing packaging material waste and reducing production costs.

-

Full-Servo Control System

- Executes actions using a full-servo control system, achieving high-speed, high-precision operations that enhance packaging efficiency and accuracy.

-

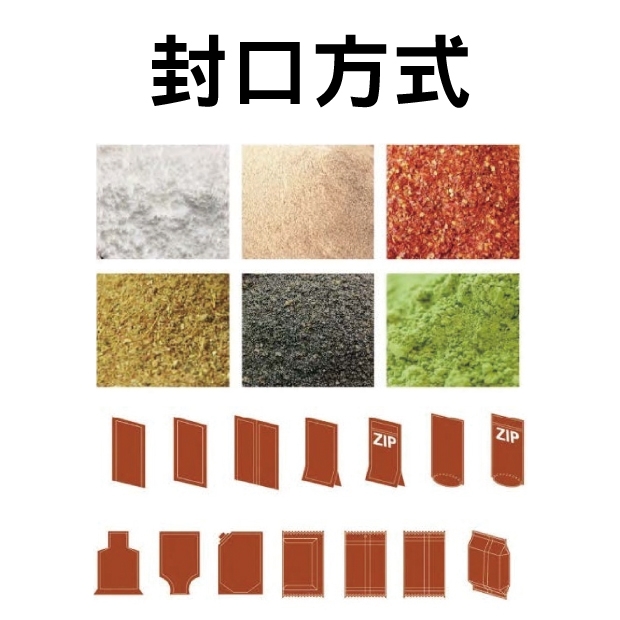

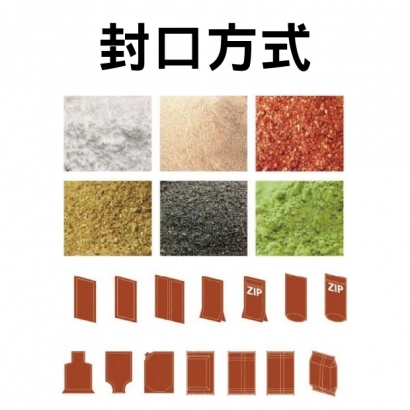

Diverse Packaging Forms

- Supports various pre-made bag types, including flat bags, stand-up bags, zipper bags, and M-bags, catering to different market demands and product characteristics.

-

Complies with International Standards

- The equipment complies with GMP standards and has CE certification, ensuring safety and quality, and suitable for export and international market demands.

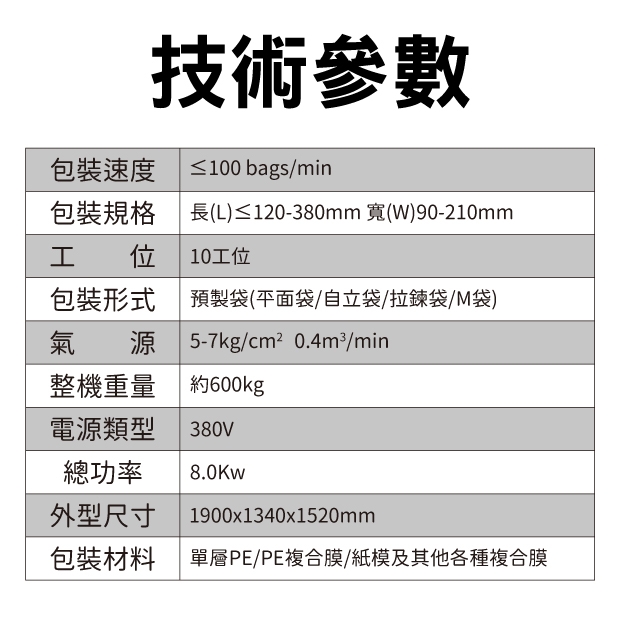

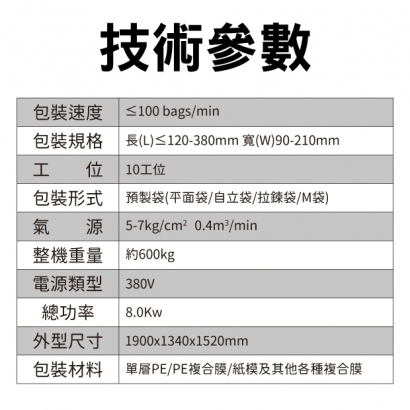

Technical Specifications

- Packaging Speed: <100 cans/minute

- Packaging Specifications: Length (L) 120-380mm, Width (W) 90-210mm

- Station Count: 10 stations

- Packaging Forms: Pre-made bags (flat bags, stand-up bags, zipper bags, M-bags, etc.)

- Air Supply Requirement: 5-7 Kg/cm², 0.4 m³/min

- Machine Weight: Approximately 600 kg

- Power Requirement: 380V, Total power 8.0 kW

- Dimensions: 1900×1340×1520mm

- Packaging Materials: Single-layer PE, PE composite film, paper film, and other composite films

Application Scenarios

INPHIC's Powder Ten-Station Rotary Belt Bagging Machine is widely used in:

-

Food Industry

- Products such as milk powder, coffee powder, protein powder, cocoa powder, seasoning powders, coffee, chili powder, curry powder, five-spice powder, flour, etc., providing efficient and precise packaging solutions.

-

Pharmaceutical Industry

- For Chinese herbal powders, pepper powders, dietary supplements, etc., ensuring accurate measurement and packaging hygiene.

-

Chemical Industry

- Applicable to powdered chemicals and small granular materials, meeting the industry’s high demands for efficiency and safety.

-

Other Industries

- Beauty, household cleaning products, laundry powders, baking powders, etc., supporting diverse packaging designs to enhance market competitiveness.

Specific Applications in the Food Industry:

- Seasoning Packaging: Such as pepper, salt, sugar, chili powder, etc., these powdered products require moisture resistance and anti-clumping properties. The INPHIC powder bagging machine effectively protects their quality and maintains long-term stability and flavor.

- Milk Powder and Baby Food: Milk powder, nutritional powders, etc., need to maintain high-quality powdered consistency. This equipment can precisely measure and prevent powder waste while avoiding the impact of moist environments on product quality.

- Coffee Powder Packaging: For coffee powders, which are finely powdered, the bagging machine ensures that every bag has a perfect seal and maintains the freshness of the powder, preserving the original aroma and flavor of the coffee.

- Instant Powder Products: Such as instant soup mixes, preparation powders, etc., these powdered products have high demands for shelf life and packaging precision. The vacuum packaging effect of this equipment can effectively extend shelf life and retain flavor.

- Pharmaceutical Powders: Like pharmaceutical powder packaging, this equipment ensures the precise dosing of each portion and fully complies with relevant hygiene and quality standards.

Contact INPHIC to Explore High-Efficiency Powder Packaging Solutions, Helping to Enhance Production Efficiency and Product Market Competitiveness!

INPHIC's Powder Ten-Station Rotary Belt Bagging Machine is a top-tier equipment for the powdered food packaging market, featuring high-precision measurement systems and intelligent control technologies. It meets the diverse packaging needs of the food industry, pharmaceutical industry, and chemical industry. The equipment supports a variety of pre-made bag types and is a professional choice in the powdered bagging machine and rotary bagging machine markets.