INPHIC Granule Measuring Cup Rounded Corner Packaging Machine

The INPHIC Granule Measuring Cup Rounded Corner Packaging Machine is a highly efficient, fully automated packaging solution designed for granular products. Combining advanced measuring cup technology and rounded corner bag cutting functionality, this machine not only enhances production efficiency but also improves packaging aesthetics and safety. It is ideal for the food, pharmaceutical, chemical, and cosmetics industries, meeting diverse packaging needs.

Product Features and Advantages

-

Wide Industry Applications

- Suitable for food (e.g., candy, nuts, grains, sugar sachets, instant drinks), pharmaceuticals (e.g., medicinal granules), chemicals (e.g., granular chemicals), and the cosmetics industry, meeting the packaging needs for various granular products.

-

Fully Automated Operation

- Automatically completes bag making, measuring, filling, sealing, cutting, and counting processes. Supports additional features such as batch code printing, eliminating manual intervention and significantly improving production efficiency.

-

High-Precision Control System

- Utilizes a PLC control system with a touch-screen interface, ensuring stable performance and user-friendly operation.

- The intelligent temperature controller with PID adjustment technology maintains sealing temperature errors within ±1°C, ensuring consistent and high-quality seals.

-

Measuring Cup Technology

- Incorporates a measuring cup rotary system to deliver high-precision measurement, particularly suited for the efficient packaging of granular products while reducing material waste.

-

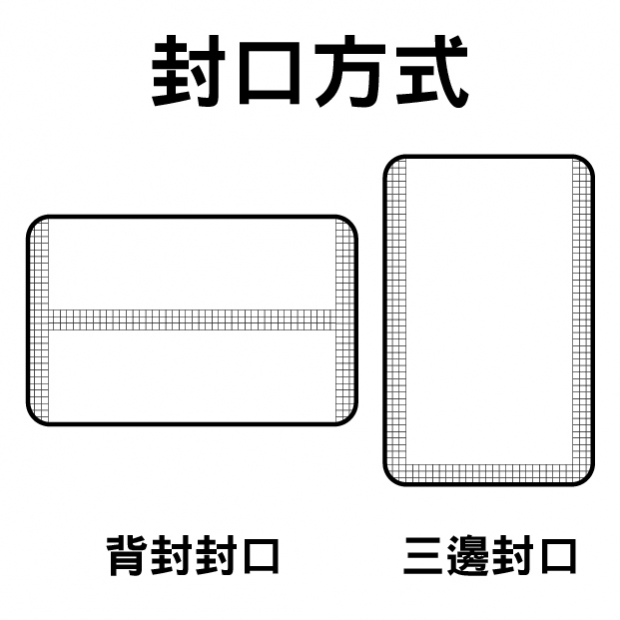

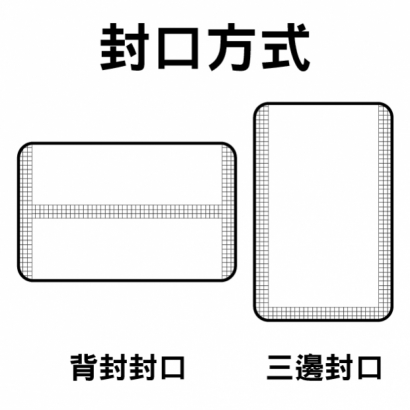

Rounded Corner Bag Cutting

- Special rounded corner cutting design enhances packaging aesthetics and eliminates sharp edges, improving user safety and experience.

-

Support for Diverse Packaging Materials

- Compatible with a variety of packaging materials, including polypropylene/polyethylene, aluminum foil/polyethylene, polyester/aluminized/polyethylene, and others, ensuring excellent sealing performance and versatile packaging options.

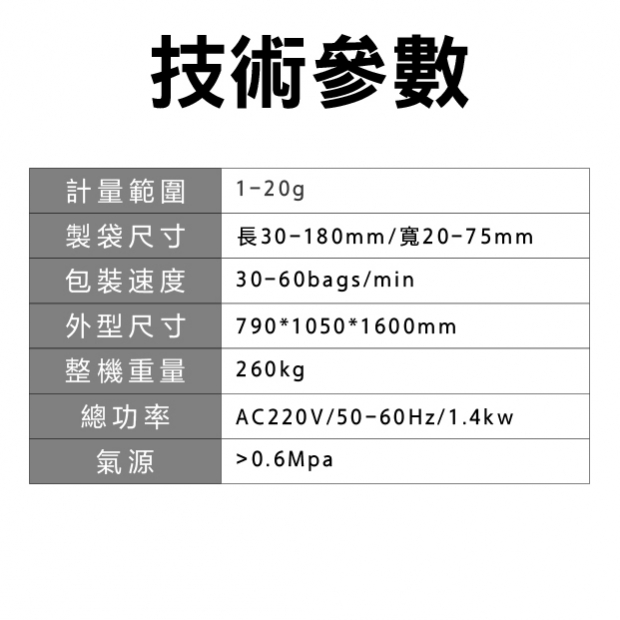

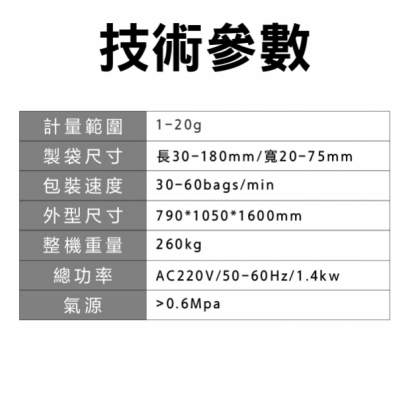

Technical Specifications

- Measuring Range: 1-200g

- Bag Size: Length 30-180mm, Width 20-75mm

- Packaging Speed: 30-60 bags/min

- Machine Dimensions: 790×1050×1600mm

- Machine Weight: 260kg

- Total Power: 220V, 50-60Hz, 1.4kW

- Air Source Requirement: >0.6Mpa

Application Scenarios

-

Food Industry

- Ideal for precise packaging of candy, nuts, grains, and coffee beans, ensuring product consistency and market appeal.

-

Pharmaceutical Industry

- Perfect for packaging medicinal granules and health supplements, ensuring accurate measurement and compliance with hygiene standards.

-

Chemical and Cosmetics Industries

- Suitable for packaging granular chemicals and beauty granule products, providing stable and efficient packaging support.

Packaging Features and Market Value

- The rounded corner bag design significantly enhances the visual appeal and user experience, ideal for high-end market positioning.

- Ensures packaging safety during transport and use, eliminating risks associated with sharp edges.

Contact INPHIC Now to Explore Efficient Granule Packaging Solutions That Make Your Product Packaging More Professional, Attractive, and Market-Ready!

The INPHIC Granule Measuring Cup Rounded Corner Packaging Machine is a professional solution for food and granular product packaging. Designed for rounded corner bag cutting and incorporating advanced measuring cup technology with automated control systems, this machine provides stable and reliable packaging support. It is particularly ideal for high-end food packaging such as candy and nut packaging machines, enhancing market competitiveness and consumer experience.