INPHIC Large-Capacity Powder Screw Packaging Machine

The INPHIC Large-Capacity Powder Screw Packaging Machine is a high-efficiency powder packaging solution designed for large packaging needs. Its sealed design and dust extraction system significantly reduce dust pollution, while the transparent hopper allows for material monitoring. The flexible measurement system ensures precision and efficiency, making it particularly suitable for large-capacity powder packaging in the food, pharmaceutical, chemical, and other industries.

Product Features and Advantages

-

High-Efficiency Dust Control

- Sealed Bag Clamping System: Prevents dust leakage, ensuring a clean operating environment.

- Built-in Dust Extraction System: Effectively controls dust dispersion, enhancing safety and comfort in the workspace.

-

Flexible Measurement Modes

- Supports both volumetric measurement and weight measurement with seamless switching:

- Small-scale packaging uses screw feeding with electronic scale feedback control.

- Large packaging uses simultaneous feeding and weighing, achieving packaging accuracy of ±1g.

- Supports both volumetric measurement and weight measurement with seamless switching:

-

Intelligent Operation and Control

- Touch-screen interface with a PLC intelligent control system and servo motor ensures precise feeding, easy adjustment, and stable, reliable packaging processes.

-

Transparent Hopper Design

- The transparent hopper allows clear visibility of material flow, while a flexible material level detection switch prevents empty runs or sensor faults.

-

Designed for Large Capacity

- With a maximum measurement range of 25kg, it is ideal for high-volume production scenarios, ensuring accuracy and efficiency.

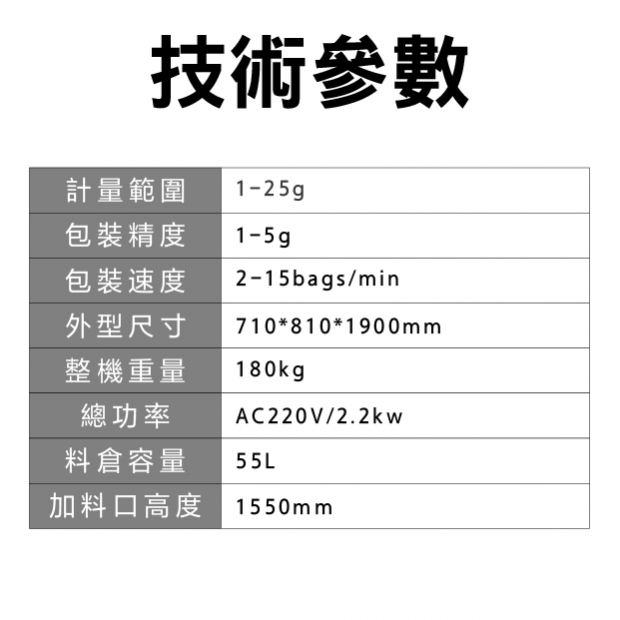

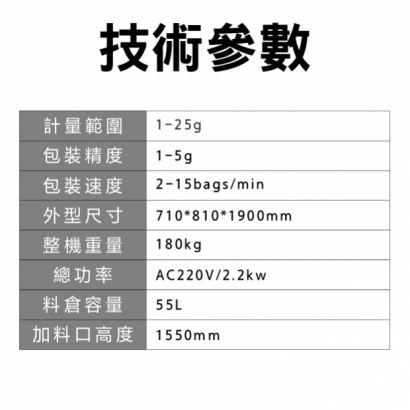

Technical Specifications

- Measurement Range: 1-25kg

- Packaging Accuracy: ±1-5g

- Packaging Speed: 2-15 bags/min

- Hopper Capacity: 55L

- Total Power: 2.2kW

- Power Supply: AC220V

- Machine Dimensions: 710×810×1900mm

- Machine Weight: 180kg

Application Scenarios and Industry Relevance

-

Food Industry

- Ideal for packaging milk powder, protein powder, coffee powder, and large-batch seasoning powders, ensuring precise measurement and tight seals.

-

Pharmaceutical Industry

- Perfect for Chinese medicinal powders and large-quantity health supplement powders, meeting the industry’s high precision and hygiene standards.

-

Chemical Industry

- Suitable for chemical powders, additives, and other large-capacity products, providing stable, efficient packaging solutions while ensuring consistency.

-

Other Industries

- Applicable for agricultural fertilizers, animal feed powders, and other large-scale production environments.

Packaging Features and Market Advantages

- Large Capacity and High Precision: Designed for large packaging scenarios, ensuring product consistency and quick market response.

- Environmentally Friendly Design: Reduces dust pollution, improves workplace safety, and aligns with modern environmental standards.

- Flexible Application: Supports various packaging needs for different product types and specifications.

Contact INPHIC to Explore More Large-Scale Powder Packaging Solutions and Enhance Your Production Efficiency and Market Competitiveness!

The INPHIC Large-Capacity Powder Screw Packaging Machine is specifically designed for large-scale powder packaging, combining high-precision screw metering technology with intelligent operation systems. It is ideal for applications such as milk powder packaging, protein powder packaging, and chemical powder packaging. With its stable performance and precise measurement, this machine helps businesses improve production efficiency and product quality—making it the perfect solution for the food, pharmaceutical, and chemical industries.