INPHIC Automatic Liquid Rounded Corner Packaging Machine

The INPHIC Automatic Liquid Rounded Corner Packaging Machine is a highly efficient, fully automated packaging solution designed for liquid and sauce products. Featuring a rounded corner cutting function, it enhances the safety and aesthetics of packaging. Combined with intelligent control technology, it delivers stable and efficient packaging operations to meet the diverse needs of the food, pharmaceutical, chemical, and cosmetics industries. This equipment significantly boosts production efficiency while ensuring consistent product quality.

Product Features and Advantages

-

Wide Industry Applications

- Ideal for food products (e.g., salad dressings, juices, liquid supplements, jams, olive oil, chili sauces, ketchup), pharmaceuticals (e.g., liquid medicines, enzymes, lutein), chemicals (e.g., cleaning liquids, detergents, shampoos), and cosmetics (e.g., skincare liquids, serums).

-

Rounded Corner Cutting Design

- The rounded corner bag design enhances packaging aesthetics and eliminates sharp edges, improving user safety and experience—ideal for high-end market products.

-

Fully Automated Operation

- Completes bag making, measuring, filling, sealing, cutting, and counting processes automatically, eliminating the need for manual intervention and supporting batch code printing to meet various production needs.

-

Precision Control and Stable Performance

- The PLC intelligent control system and touch-screen interface simplify operations, while the servo motor ensures precise bag length control and high product consistency.

- An intelligent temperature controller with PID adjustment technology keeps sealing temperature errors within ±1°C, guaranteeing perfect sealing and aesthetics.

-

Support for Diverse Packaging Materials

- Compatible with various materials, including polypropylene/polyethylene, aluminum foil/polyethylene, polyester/aluminized/polyethylene, reinforced polyethylene, and paper/polyethylene, ensuring excellent moisture resistance and freshness preservation.

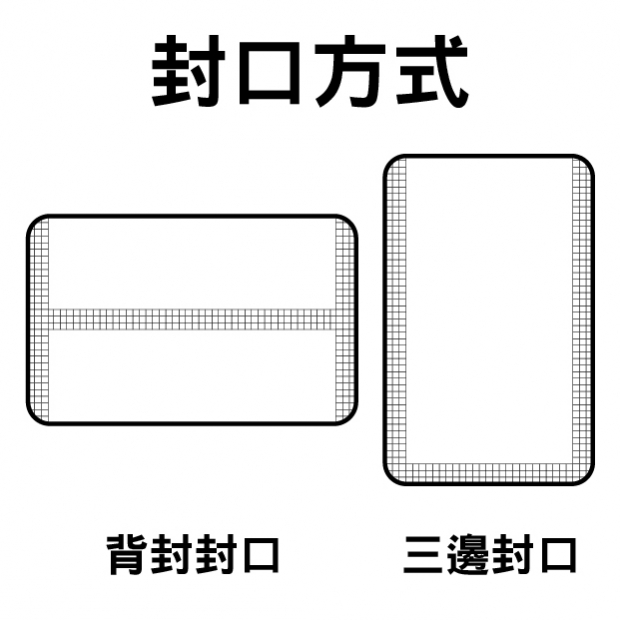

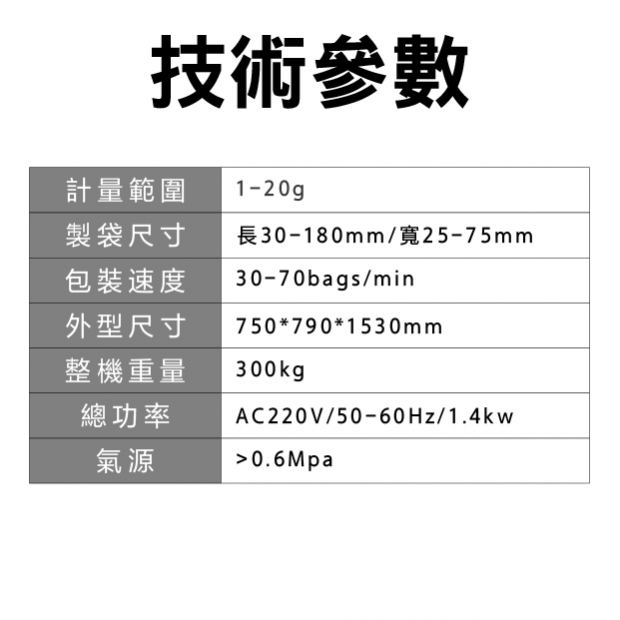

Technical Specifications

- Measuring Range: 1-20g

- Bag Size: Length 30-180mm, Width 25-75mm

- Packaging Speed: 30-70 bags/min

- Machine Weight: 300kg

- Machine Dimensions: 750×790×1530mm

- Total Power: 1.4kW

- Power Supply: AC220V, 50-60Hz

- Air Source Requirement: >0.6Mpa

Industry Application Scenarios

-

Food Industry

- Perfect for packaging salad dressings, ketchup, honey, juices, and soy sauce, ensuring attractive packaging and product stability to meet high-end market demands.

-

Pharmaceutical Industry

- Ideal for packaging liquid medicines and small health supplement sachets, providing precise measurement and reliable sealing to meet hygiene standards.

-

Cosmetics Industry

- Suitable for skincare liquids, serums, and toners, enhancing product branding and market appeal with premium packaging.

-

Chemical Industry

- Applicable for packaging cleaning liquids, chemical reagents, and other products, ensuring tight and safe packaging solutions.

Packaging Features and Market Advantages

- Safe Design: Rounded corners eliminate safety risks, enhancing user convenience and consumer satisfaction.

- Efficient Production: Fully automated operation reduces labor costs, making it ideal for medium to large-scale production.

- Flexible Adaptability: Supports various packaging materials and sizes, meeting diverse market needs.

Contact INPHIC to Discover More Rounded Corner Liquid Packaging Solutions and Enhance Your Product Quality and Market Competitiveness!

The INPHIC Automatic Liquid Rounded Corner Packaging Machine is specifically designed for the liquid packaging market, making it the ideal solution for salad dressing packaging, liquid condiment packaging, and skincare liquid packaging. Its rounded corner cutting function and efficient automated operation make it a perfect choice for food, pharmaceutical, and cosmetics packaging applications.

(Live Machine Demonstration - Same Model Configured for Powder Materials: Measuring Cup Device, Automatic Feeding System, and Three-Side Sealed Aluminum Foil Bags for Testing)