INPHIC Automatic Liquid Shaped Bag Packaging Machine

The INPHIC Automatic Liquid Shaped Bag Packaging Machine is a high-efficiency solution specifically designed for shaped bag packaging, combining innovative bag designs with fully automated technology to enhance product market competitiveness. Shaped bags, as an upgraded packaging form, offer exceptional design flexibility, including streamlined, dynamic shapes, or custom designs tailored to brand characteristics. This machine supports multiple bag types, such as arc-shaped easy-tear bags, spout bags, and curved shaped bags, merging functionality with visual appeal—ideal for high-end market positioning. Shaped bags provide convenient portability and usage, offering consumers a safer and more comfortable experience that aligns with current trends.

Product Features and Advantages

-

Wide Industry Applications

- Designed for food products (e.g., sauces, honey, salad dressings), cosmetics (e.g., skincare liquids, serums), pharmaceuticals (e.g., liquid medicine), and chemicals (e.g., liquid reagents).

-

Shaped Bag Packaging

- Supports shaped bag production, enhancing packaging aesthetics and brand recognition—perfect for high-end market products.

-

Fully Automated Operation

- Completes processes such as bag making, measuring, filling, sealing, cutting, and counting in a fully automated workflow, reducing manual intervention and improving production efficiency.

- Customizable functions like batch code printing meet diverse market needs.

-

Intelligent Operation and Precision Control

- Features PLC intelligent control and a touch-screen interface, with servo motor control ensuring precise bag dimensions and stable performance.

- Equipped with an intelligent temperature controller, PID adjustment technology keeps sealing temperature errors within ±1°C, ensuring perfect sealing results.

-

Support for Multiple Packaging Materials

- Compatible with PE composite film, pure aluminum film, and aluminized film, offering superior moisture and oxidation resistance to maintain product freshness and quality stability.

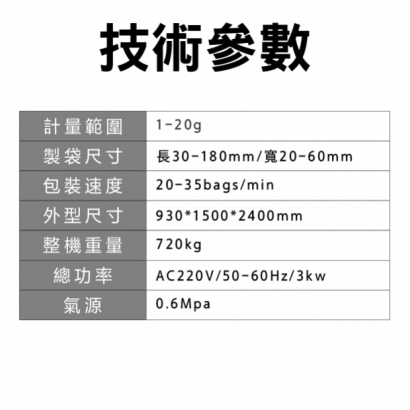

Technical Specifications

- Measuring Range: 1-20g

- Bag Size: Length 30-180mm, Width 20-60mm

- Packaging Speed: 20-35 bags/min

- Machine Weight: 720kg

- Machine Dimensions: 930×1500×2400mm

- Total Power: 3kW

- Power Supply: AC220V, 50-60Hz

- Air Source Requirement: 0.6Mpa

Industry Applications

-

Food Industry

- Ideal for packaging jams, honey, salad dressings, and concentrated juices, meeting high-end food market demands for shaped packaging and boosting product appeal.

-

Cosmetics Industry

- Suitable for packaging skincare liquids, serums, and cosmetic toners with premium shaped bag designs, enhancing brand image and market value.

-

Pharmaceutical Industry

- Used for small liquid medicine and health supplement packaging, ensuring precise dosing and reliable sealing performance to meet hygiene standards.

-

Chemical Industry

- Applicable for chemical reagents and liquid products in shaped bags, providing oxidation-resistant and moisture-proof packaging solutions to extend product shelf life.

Packaging Features and Market Advantages

- Innovative Design: Shaped bags enhance product aesthetics and appeal, ideal for premium market brand positioning.

- Efficient and Stable: Fully automated operation and intelligent controls ensure stable production performance, suitable for medium to large-scale production.

- Flexible Adaptability: Supports various packaging materials and bag designs, meeting diverse product needs and market differentiation strategies.

Contact INPHIC to Learn More About Liquid Shaped Bag Packaging Solutions and Achieve Efficient Production with Enhanced Market Competitiveness!

The INPHIC Automatic Liquid Shaped Bag Packaging Machine is the top choice for food, shaped bag, and liquid packaging markets. Its intelligent operating system and innovative shaped bag design make it the ideal solution for salad dressing packaging, jam packaging, and skincare liquid packaging, meeting multi-scenario needs while enhancing production efficiency and product value.