INPHIC Liquid Shaped Bag Four-Station Packaging Machine

The INPHIC Liquid Shaped Bag Four-Station Packaging Machine combines innovative design and high efficiency, specifically developed to meet the packaging needs of liquid and sauce-shaped bags. Utilizing a four-station synchronized operation structure, this machine efficiently produces four packages per cycle. INPHIC also offers customized multi-station production lines to meet varying client requirements, significantly enhancing production efficiency—ideal for medium to large-scale production environments. Shaped bags, as a premium packaging format, provide unique design options such as streamlined, easy-tear, curved, or spout designs. These not only enhance market appeal but also improve user experience.

This machine is optimized for shaped bag production, ensuring beautiful bag shapes, tight seals, and consistent dimensions. Featuring advanced intelligent control systems (PLC control) and precision servo motors, it achieves accurate control over bag length, measurement, and filling processes, ensuring a perfect blend of functionality and appearance for each product. The unique design flexibility of shaped bags, combined with diverse packaging needs, gives unmatched advantages in high-value product sectors like juices, enzymes, and liquid supplements, helping brands stand out in competitive markets.

Product Features and Advantages

-

Multi-Station Synchronized Operation

- Four-station design allows simultaneous packaging of four products, significantly boosting production efficiency—ideal for medium to large-scale production.

-

Shaped Bag Packaging Features

- Supports various shaped bag designs, such as streamlined bags, juice bags, and liquid supplement bags, enhancing product aesthetics and usability.

- Innovative packaging design suitable for high-end markets, increasing product recognition and market appeal.

-

Fully Automated Operation

- Automatically completes bag making, measuring, filling, sealing, cutting, and counting, reducing manual intervention and improving production stability and accuracy.

- Supports batch code printing and other functionalities to meet diverse production needs.

-

Precision Control and High Efficiency

- PLC intelligent control and touch-screen interface with servo motor precision control ensure consistent bag length and dimensions.

- The intelligent temperature controller with PID adjustment minimizes sealing temperature errors to within ±1°C, ensuring perfect sealing results.

-

Comprehensive Safety Features

- Equipped with intelligent alarms for open-door stops, high/low temperature alerts, and low air pressure stops, ensuring safe and stable production.

-

Support for Various Packaging Materials

- Compatible with PE composite film, pure aluminum film, aluminized film, and nylon materials, providing excellent moisture and oxidation resistance to suit various product needs.

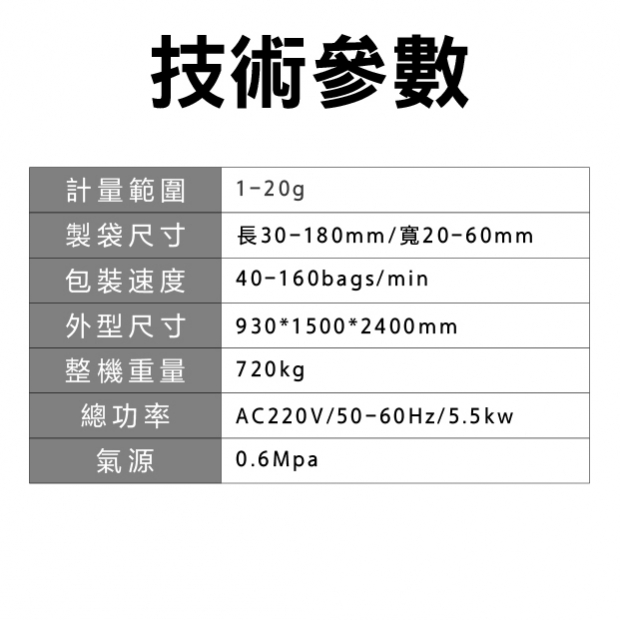

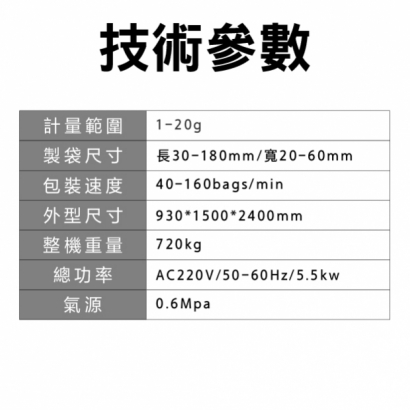

Technical Specifications

- Measuring Range: 1-20g

- Bag Size: Length 30-180mm, Width 20-60mm

- Packaging Speed: 40-160 bags/min

- Machine Weight: 720kg

- Machine Dimensions: 930×1500×2400mm

- Total Power: 5.5kW

- Power Supply: AC220V, 50-60Hz

- Air Source Requirement: 0.6Mpa

Industry Application Examples

-

Food Industry

- Ideal for premium shaped bag packaging of juices, enzymes, liquid supplements, and salad dressings, enhancing product appeal and market value.

-

Cosmetics Industry

- Suitable for packaging skincare liquids and serums in shaped bags, meeting brand demands for innovative packaging designs.

-

Pharmaceutical Industry

- Perfect for small liquid medicine and health supplement packaging, ensuring precise measurement and secure seals to meet hygiene standards.

-

Chemical Industry

- Applicable for liquid chemicals and cleaning product packaging, providing leak-proof and secure solutions.

Packaging Features and Market Advantages

- Innovative Shaped Bags: Unique shaped bag designs enhance product aesthetics and brand recognition, ideal for premium market positioning.

- High-Efficiency Multi-Station: Four-station synchronized operation dramatically increases production efficiency, ideal for batch production.

- Comprehensive Safety: Multi-alarm systems ensure operational safety and minimize production risks.

Contact INPHIC Now to Explore Efficient Solutions for Liquid Shaped Bag Packaging and Elevate Your Product Packaging to a Higher Standard!

The INPHIC Liquid Shaped Bag Four-Station Packaging Machine is the ideal solution for high-end food and cosmetics packaging markets. Its innovative shaped bag design and efficient four-station synchronized operation make it particularly suitable for juice packaging, liquid supplement packaging, and skincare liquid packaging, helping businesses enhance production efficiency and product value.