INPHIC Measuring Cup Inner and Outer Tea Bag Packaging Machine

The INPHIC Measuring Cup Inner and Outer Tea Bag Packaging Machine is a high-efficiency packaging solution designed for tea and health teas. Its key feature is achieving integrated inner and outer bag packaging, completing the production, filling, and sealing of both inner and outer bags in one process. This eliminates contamination and time delays caused by traditional separate packaging processes. The inner and outer bag design enhances product protection, hygiene, and consumer experience while delivering a premium product appearance.

The machine adopts measuring cup technology, specializing in the precise measurement of small granular materials (e.g., tea leaves, herbs, and health teas), ensuring uniform content in every bag. The inner bag uses breathable tea filter materials, such as non-woven fabric, nylon mesh bags, triangular mesh bags, and eco-friendly corn fiber, while the outer bag uses composite film with labels. This combination provides efficient moisture protection and boosts market appeal. Additionally, the compatibility with drip tea bags and cold brew tea bags makes it an ideal choice for the premium tea beverage market.

By integrating inner and outer bag packaging with measuring cup technology, this machine significantly enhances production efficiency while ensuring product quality consistency and hygiene standards, creating new opportunities for the tea beverage industry.

Product Features and Advantages

-

Integrated Inner and Outer Bag Packaging

- Achieves simultaneous packaging of inner and outer bags, avoiding contamination during intermediate transfers and significantly improving hygiene and packaging efficiency.

-

Support for Multiple Packaging Formats

- Suitable for drip tea bags and cold brew tea packaging, meeting market demands for convenience and innovation.

-

Accurate Bag Length Control

- Utilizes stepper motor control for inner and outer bag film pulling, ensuring stable bag length and precise positioning to avoid packaging deviations.

-

Precision Temperature Control

- PID temperature control technology ensures precise adjustment of sealing temperatures, minimizing errors and delivering tightly sealed, aesthetically pleasing, and durable packaging.

-

Intelligent Operating System

- Equipped with PLC intelligent control and a user-friendly interface for intuitive operation, along with fault detection capabilities to ensure stable machine performance.

-

Compatibility with Various Packaging Materials

- Supports tea filter paper, cotton thread, composite film, and labels to meet diverse packaging needs.

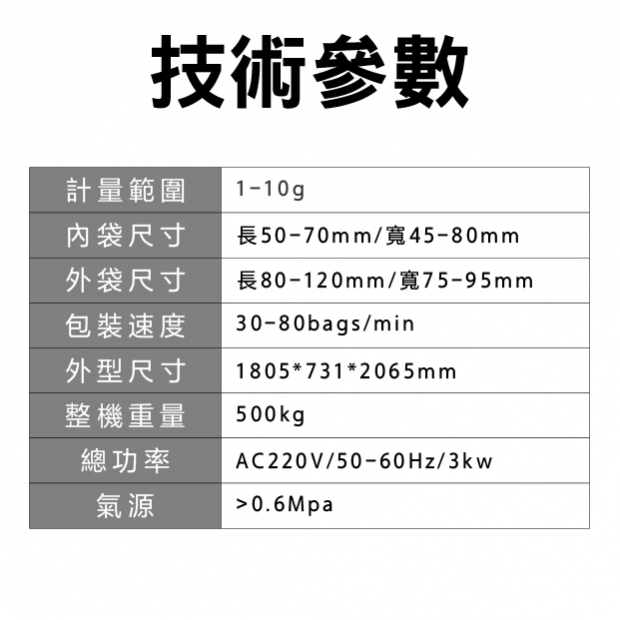

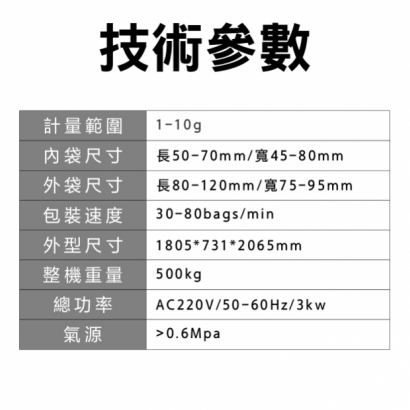

Technical Specifications

- Measuring Range: 1-10g

- Inner Bag Size: Length 50-70mm, Width 45-80mm

- Outer Bag Size: Length 80-120mm, Width 75-95mm

- Packaging Speed: 30-80 bags/min

- Machine Weight: 500kg

- Machine Dimensions: 1805×731×2065mm

- Total Power: 3kW

- Power Supply: AC220V, 50-60Hz

- Air Source Requirement: >0.6Mpa

Customer Application Scenarios

-

Tea Industry

- Ideal for packaging green tea, black tea, oolong tea, and herbal teas, ensuring precise measurement and attractive packaging.

-

Health and Medicinal Tea Industry

- Perfect for packaging medicinal herbs, wellness teas, and functional tea beverages, delivering hygienic and high-quality presentations.

-

Herbal Products

- Used for small-packaging applications of roots, herbs, and other botanical materials, offering reliable and stable packaging solutions.

-

Innovative Tea Beverage Market

- Drip tea bags and cold brew tea packaging tailored for high-end markets, meeting the demand for portability and premium tea beverages.

Packaging Features and Market Advantages

- Integrated Inner and Outer Bag Design: Simultaneous completion of inner and outer bag packaging enhances production efficiency and delivers refined packaging for premium markets.

- Efficiency and Precision: Intelligent control systems and precise measuring technologies ensure product consistency and stability in every package.

- Hygiene and Safety: Contamination-free packaging processes meet food-grade hygiene standards, enhancing brand reputation and consumer trust.

Contact INPHIC to Explore Professional Tea Bag Packaging Solutions that Enhance Market Appeal and Brand Competitiveness!

The INPHIC Measuring Cup Inner and Outer Tea Bag Packaging Machine is designed for the tea packaging market, meeting the demands of green tea packaging, drip tea packaging, and cold brew tea packaging. With integrated inner and outer bag packaging, intelligent controls, and precise measurement, it is the ideal choice for improving production efficiency and competitiveness in the tea industry.