INPHIC Ultrasonic Sealing Inner and Outer Tea Bag Packaging Machine

The INPHIC Ultrasonic Sealing Inner and Outer Tea Bag Packaging Machine is a high-efficiency packaging solution designed specifically for tea bags, drip coffee bags, and small granular materials. Featuring integrated inner and outer bag packaging functionality and advanced ultrasonic sealing technology, the machine completes the production, filling, and sealing of both inner and outer bags in a single process. This reduces contamination risks during packaging and significantly improves production efficiency. The inner bag, made of non-woven or eco-friendly materials, ensures excellent breathability and brewing performance, while the outer bag provides enhanced moisture protection and product preservation. This dual-layer packaging structure extends product shelf life and enhances market appeal.

The incorporated ultrasonic sealing technology avoids issues like weak seals or odors caused by traditional heat sealing, ensuring firm, neat, and hygienic sealing. The drip coffee bag design and refined bag shape intuitively convey premium product quality, enhancing the user experience—making it ideal for international tea and coffee brands. This machine not only meets the demands for efficient automated production but also helps businesses create innovative packaging formats to strengthen their competitiveness in the market.

Product Features and Advantages

-

Drip Coffee Bag Filter Design

- Three-Side Sealed Drip Bag: The drip bag structure is sturdy, allowing it to hang directly on the cup rim for convenient brewing. Its breathable filter ensures superior filtration and brewing performance for coffee or tea.

- Aesthetic Bag Shape: The clean and refined bag shape meets premium product standards for international markets, making it ideal for drip coffee and brewing tea bags.

-

Ultrasonic Sealing Technology

- Uses ultrasonic sealing technology to avoid odors and unstable seals often caused by heat sealing. It ensures that each bag is firmly, neatly, and hygienically sealed, improving packaging quality.

-

Fully Automated Operation

- Performs bag making, weighing, filling, sealing, cutting, counting, and batch number printing in a fully automated process, significantly reducing manual intervention while improving efficiency and stability.

-

Integrated Inner and Outer Bag Packaging

- The inner bag uses eco-friendly materials such as non-woven fabric, nylon, or corn fiber, while the outer bag is made of composite film. This dual-layer packaging provides superior moisture protection and product freshness while elevating product quality.

-

Multi-Functional Compatibility

- Supports the packaging of coffee powder, tea leaves, health teas, and other small granular materials, meeting diverse packaging needs across industries.

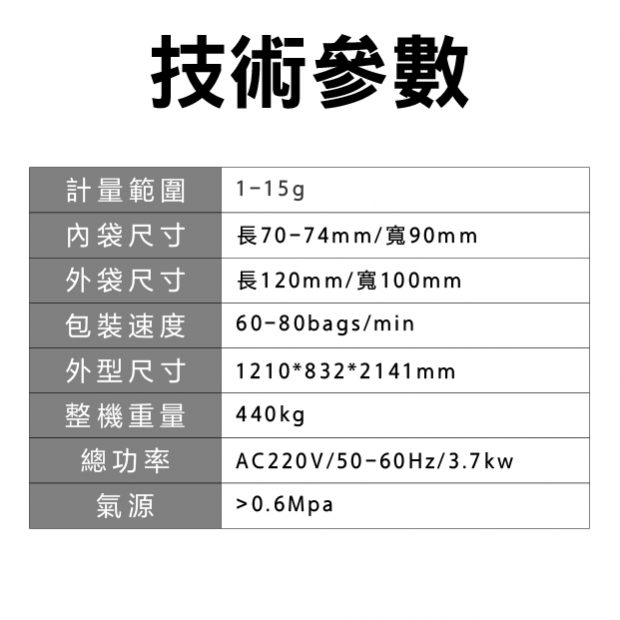

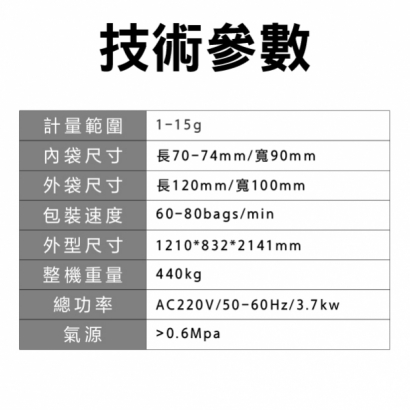

Technical Specifications

- Measuring Range: 1-15g

- Inner Bag Size: Length 70-74mm, Width 90mm

- Outer Bag Size: Length 120mm, Width 100mm

- Packaging Speed: 60-80 bags/min

- Machine Weight: 440kg

- Machine Dimensions: 1210×832×2141mm

- Total Power: 3.7kW

- Power Supply: AC220V, 50-60Hz

- Air Source Requirement: >0.6Mpa

Application Scenarios and Industry Relevance

-

Coffee Industry

- Perfect for premium drip coffee bag packaging, enhancing brewing convenience and market appeal.

-

Tea Industry

- Supports inner and outer bag packaging for tea, herbal teas, and medicinal teas, offering high-quality and diversified packaging solutions.

-

Health Food Industry

- Ideal for packaging functional herbal products, ensuring accurate measurement and stable sealing performance.

Packaging Features and Market Advantages

- Integrated Inner and Outer Bag Design: Efficiently completes dual-layer packaging, enhancing product appearance and protection to meet international market demands.

- Innovative Drip Bag Design: Portable drip coffee bag structure improves user experience and supports high-end market entry.

- Ultrasonic Sealing Advantage: Provides secure, hygienic sealing to ensure product quality and stability.

- Eco-Friendly and Versatile Materials: Inner bags made from materials like corn fiber align with green production trends, adding value to the brand.

Contact INPHIC Now to Learn More About Inner and Outer Tea Bag Packaging Solutions, Helping Your Products Lead Market Trends and Enhance Brand Value!

The INPHIC Ultrasonic Sealing Inner and Outer Tea Bag Packaging Machine is a premium solution designed for drip coffee and tea bag markets. With its drip bag design, ultrasonic sealing, and full automation, it is particularly suitable for coffee packaging, tea packaging, and health tea bag machine applications, helping businesses enhance product competitiveness.

(Video 1 - Similar Model: Ultrasonic Sealing Inner and Outer Tea Bag Packaging Machine - Customer Application Example: Non-Woven Tea Bags, Nylon Tea Bags, Corn Fiber Tea Bags)

(Video 2 - Similar Model: Ultrasonic Sealing Inner and Outer Tea Bag Packaging Machine - Customer Application Example: Non-Woven Tea Bags, Nylon Tea Bags, Corn Fiber Tea Bags)

(Video 3 - Similar Model: Ultrasonic Sealing Inner and Outer Tea Bag Packaging Machine - Customer Application Example: Non-Woven Tea Bags, Nylon Tea Bags, Corn Fiber Tea Bags)