INPHIC Tea Bag Weighing and Inner Bag Packaging Machine

The INPHIC Tea Bag Weighing and Inner Bag Packaging Machine is an innovative piece of equipment that combines precise weighing, efficient automation, and flexible packaging options. Specifically designed for various tea bags and granular materials, its core feature lies in the seamless integration of inner bag packaging and precise weighing, delivering fully automated processes from measurement to bag making and sealing. This ensures that each tea bag maintains accurate weight and firm sealing, meeting market demands for high-quality packaging. Additionally, the machine supports both flat bags and triangular pyramid bags, offering a blend of classic and modern styles. The triangular design effectively releases the tea’s aroma, enhancing the consumer's brewing experience.

Equipped with imported ultrasonic sealing technology, the machine ensures that each inner bag is sealed neatly, hygienically, and securely, making it ideal for the premium tea market. Furthermore, it supports eco-friendly packaging materials such as nylon, non-woven fabric, and corn fiber, enabling companies to meet green packaging trends while delivering top-quality products. Its fully automated design covers the entire production process from feeding to finished product delivery, significantly boosting production efficiency and reducing labor costs—trusted by major Taiwanese food enterprises!

Features and Advantages

-

Versatile Packaging Options

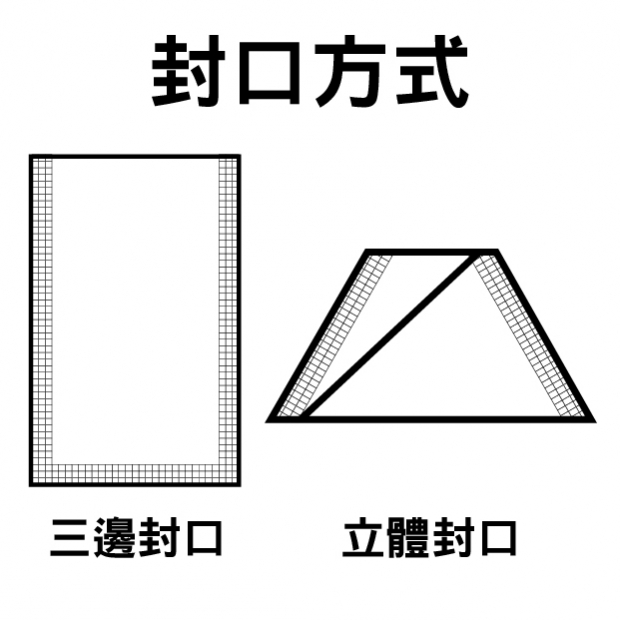

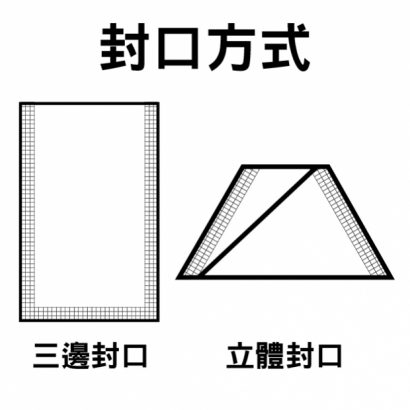

- Supports both flat bags and triangular pyramid bags to meet diverse market needs. Flat bags offer a clean, classic look, while triangular bags effectively release tea aroma for enhanced brewing results.

-

High-Precision Weighing System

- Equipped with an electronic weighing system to ensure accurate measurements for each package, minimizing material waste and maintaining product consistency.

-

Imported Ultrasonic Sealing Technology

- Utilizes imported ultrasonic sealing equipment, ensuring firm, aesthetic seals while avoiding the instability issues of traditional heat sealing techniques, ideal for premium packaging.

-

Fully Automated Operation

- Includes feeding, weighing, bag making, sealing, cutting, counting, and finished product delivery, significantly improving production efficiency and reducing dependency on labor.

-

Compatibility with Various Packaging Materials

- Supports nylon, PET, non-woven fabric, and corn fiber materials, offering excellent breathability and eco-friendly options to meet market demands for green packaging.

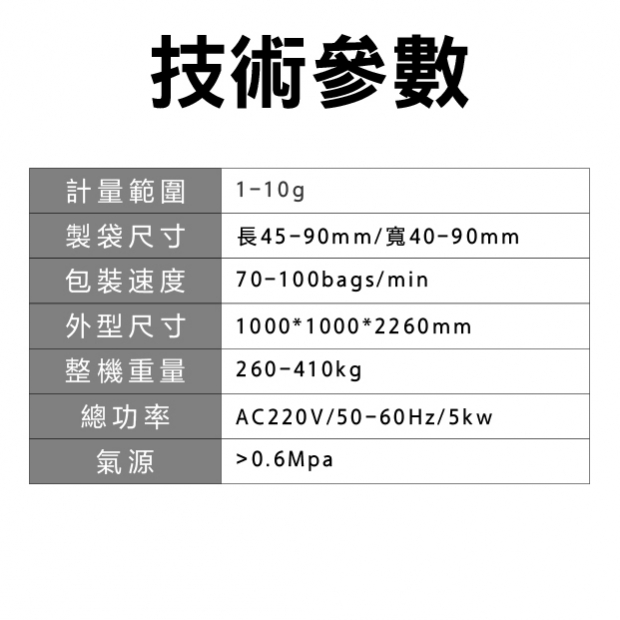

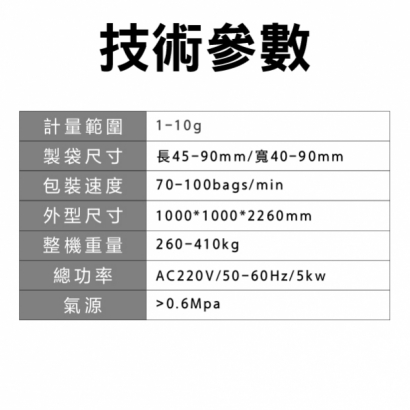

Technical Parameters

- Measurement Range: 1-10g

- Bag Size: Length 45-90mm, Width 40-90mm

- Packaging Speed: 70-100 bags/min

- Machine Weight: 260-410kg

- Machine Dimensions: 1000×1000×2260mm

- Total Power: 5kW

- Power Supply: AC220V, 50-60Hz

- Air Source Requirement: >0.6Mpa

Industry Applications

-

Tea Industry

- Ideal for packaging green tea, black tea, herbal tea, and other products, offering attractive and functional tea bag packaging to enhance market appeal.

-

Functional Tea Beverages

- Perfect for health teas, medicinal teas, and herbal teas, ensuring precise measurements and hygienic packaging to meet health-conscious consumer demands.

-

Granular Products

- Suitable for packaging other small granular products, such as herbal drinks and spice granules, providing stable and efficient packaging support.

Packaging Features and Market Advantages

- Multi-Function Packaging: Supports both flat bags and triangular pyramid bags to meet varying consumer preferences.

- High Efficiency and Stability: Fully automated operation and precise weighing systems significantly enhance production efficiency and product consistency.

- Eco-Friendly and Aesthetic: Compatible with biodegradable packaging materials, aligning with green production trends and enhancing brand image.

- Advanced Technology: Imported ultrasonic sealing technology ensures superior sealing quality and product integrity.

Contact INPHIC Now to Discover More Tea Bag Packaging Solutions and Enhance Your Product Quality and Market Competitiveness!

The INPHIC Tea Bag Weighing and Inner Bag Packaging Machine is a professional solution tailored for the tea and functional beverage markets, supporting versatile applications for flat bags and triangular pyramid bags. With imported ultrasonic sealing technology and fully automated operations, it is particularly suited for high-end markets such as tea bag packaging machines, triangular tea bag packaging, and functional beverage packaging.

(Video 1 - Real Client On-Site Machine Testing)