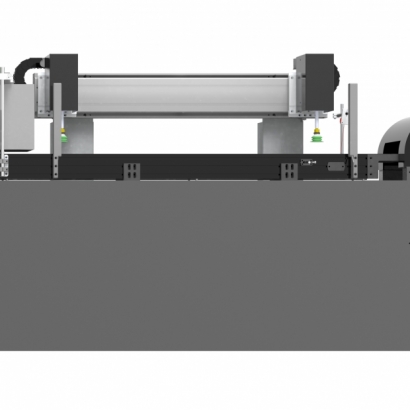

Inphic AI Intelligent Packaging Alignment Machine - Horizontal Orientation System

-

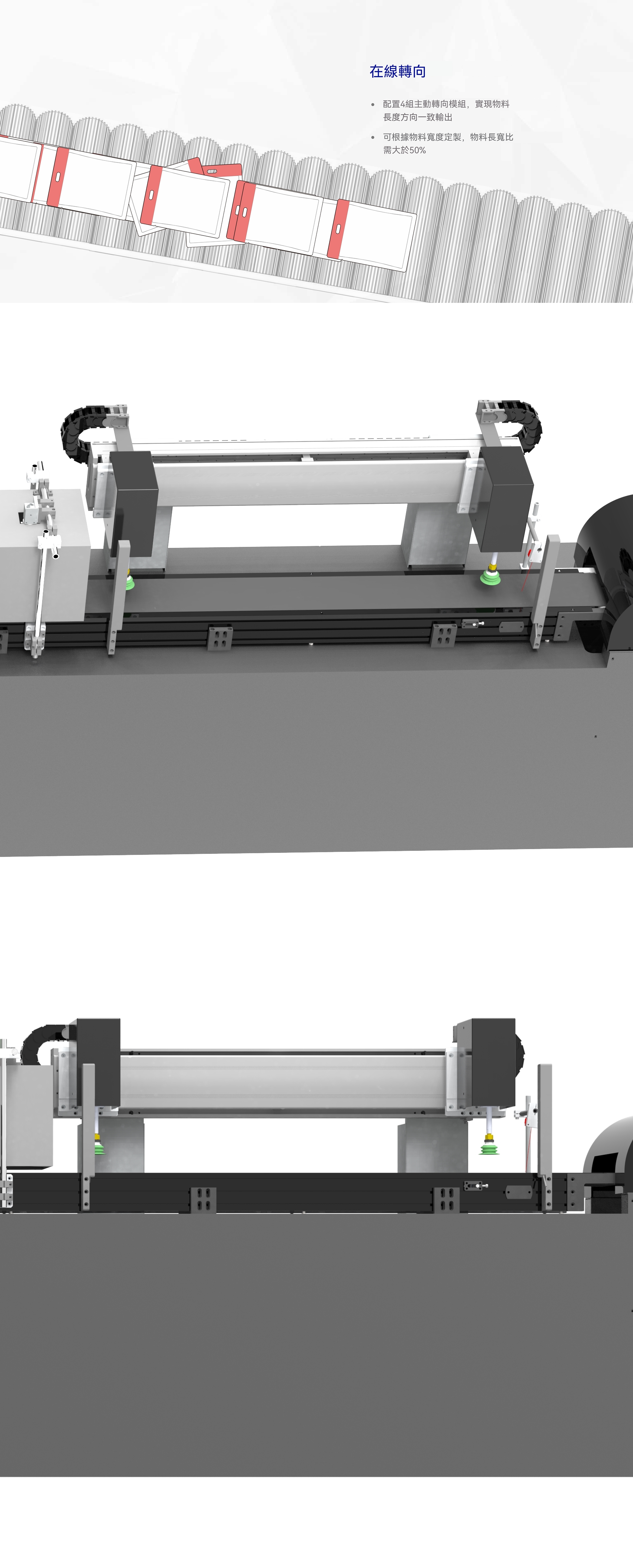

Horizontal Rotation Function

- Same-Direction Conveyance: Equipped with robotic arms, this system automatically rotates packaging bags to align them horizontally in a single direction, ensuring consistent orientation of materials during the conveyance process for streamlined packaging or inspection stages.

- Applicable Bag Types: Compatible with three-side sealed, four-side sealed, and stand-up pouches, making it efficient for packaging food, daily products, and cosmetics alike.

-

Enhanced Efficiency in Box Loading and Bag Insertion

- Smooth Operation: The horizontal orientation of packaging bags reduces manual adjustments due to inconsistent direction, significantly improving efficiency at the production line’s end.

- Fully Automated: The system’s automation minimizes human intervention, lowers error rates, and improves packaging consistency and quality.

-

Precise Control

- Position Sensing: Advanced sensing technology continuously monitors the position and orientation of packaging bags, ensuring each bag is accurately aligned.

- High Stability: The system’s stable design maintains material positioning even at high speeds, preventing drops or damage.

-

Wide Applicability

- Industry Applications: This system is versatile for use beyond food packaging, such as in the pharmaceutical, chemical, and electronics industries, meeting diverse market demands.

- Easy Upgrades: Flexible adjustments and optional features allow customization to meet varying packaging requirements.

Inphic Packaging Alignment Machine: Designed for Fully Automated Back-End Packaging Line Needs

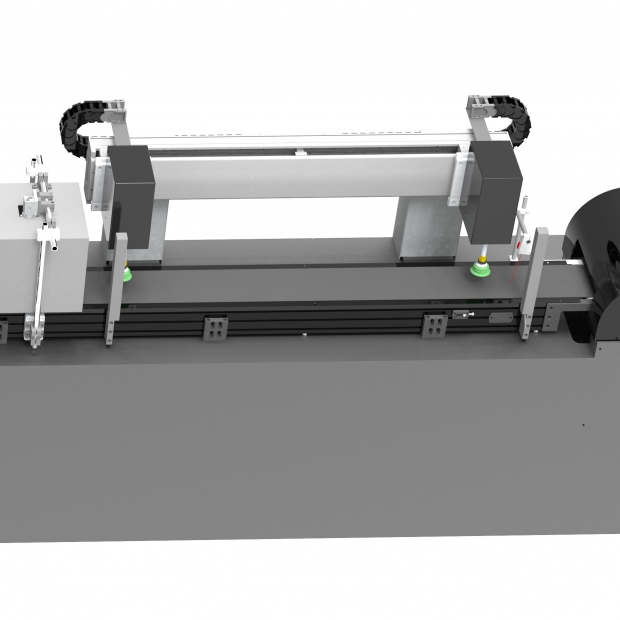

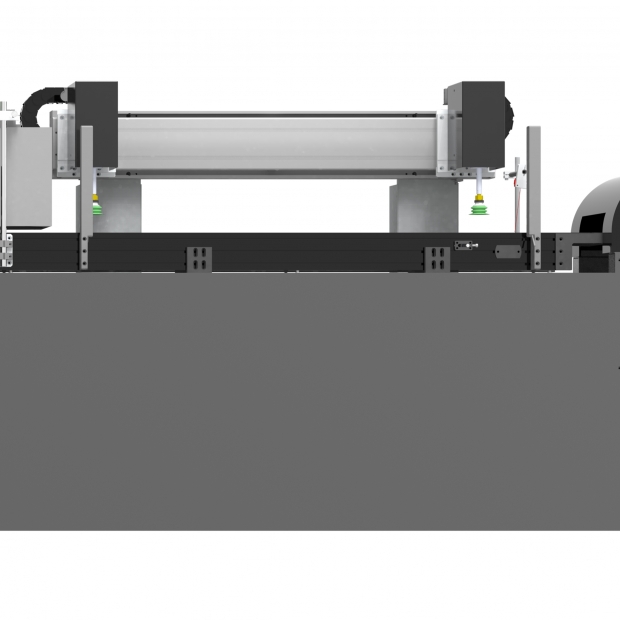

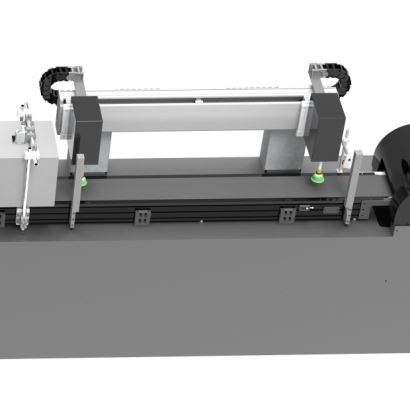

The machine features four active orientation modules to ensure consistency in the lengthwise direction of materials during output, greatly enhancing production efficiency and packaging quality. Additionally, the equipment can be customized based on material width, accommodating various packaging sizes. For optimal performance, the material’s length-to-width ratio should exceed 50%.

Whether for large-scale production or customized packaging, the Inphic AI Intelligent Packaging Alignment Machine provides outstanding performance, helping brands stand out in a competitive market.

AI-Powered High-Precision Inspection

- Built-in with multiple high-precision sensors and advanced AI inspection algorithms, the machine performs posture detection and weight measurement on each product, removing defective items (such as horizontal bags, connected bags, or underweight products) to ensure final product consistency.

- Accuracy up to 99.9%, reinforcing your brand's quality reputation.

Key Features:

- Equipped with four active orientation modules for consistent lengthwise output of materials.

- Customizable based on material width, with a length-to-width ratio requirement of over 50%.