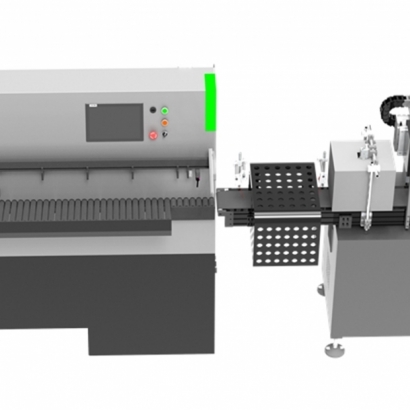

Inphic AI Intelligent Packaging Alignment Machine - Defective Product Removal System

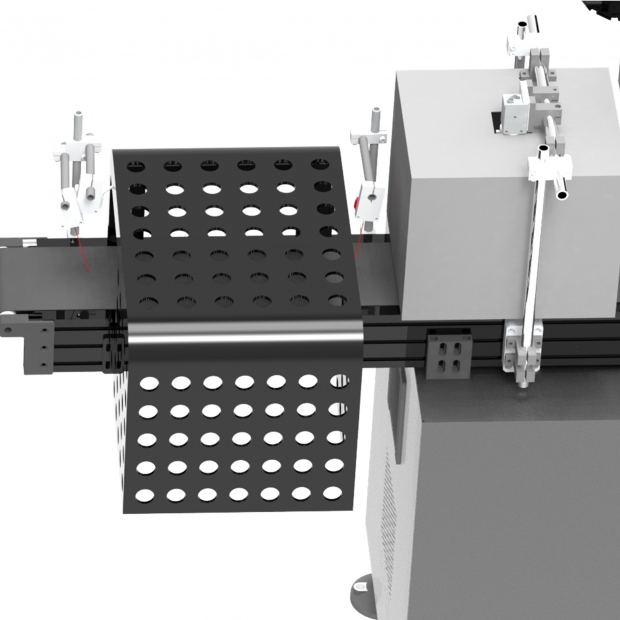

This system is equipped with an online inspection and removal function, capable of instantly identifying and rejecting defective products (such as horizontal bags, connected bags, and underweight products) to ensure the quality of each item. This technology not only reduces the outflow of defective items but also effectively lowers waste from improper packaging, enhancing the overall efficiency of the production line. Suitable for applications in food, personal care, and other industries, this optional feature is a valuable tool in quality assurance.

- System Configuration: Equipped with an online inspection function to detect and remove horizontal bag defects, ensuring consistent product output.

Inphic Packaging Alignment Machine: A Smart Solution for Fully Automated Packaging Line Back-End Needs

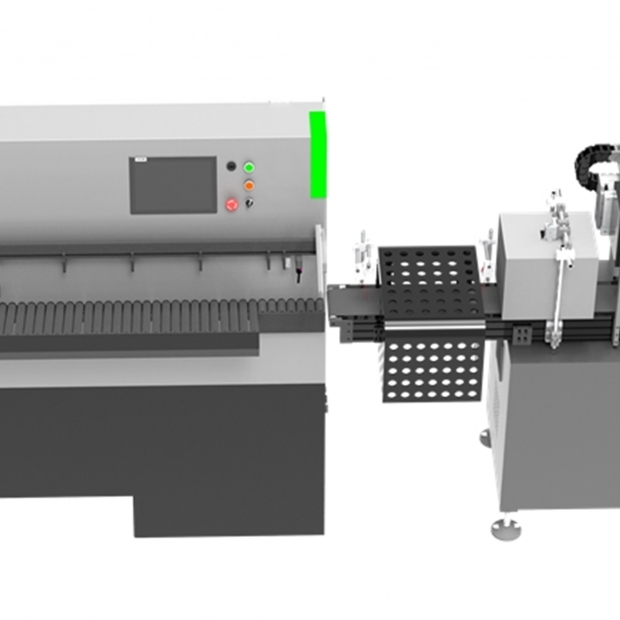

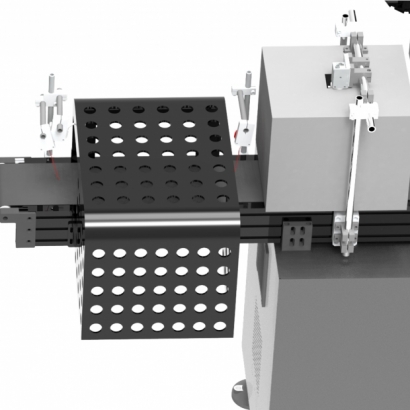

Designed specifically for the back-end of automated packaging lines, this machine includes four active orientation modules to ensure consistent lengthwise orientation of materials during output, significantly boosting production efficiency and packaging quality. Additionally, it can be customized based on material width, accommodating various packaging sizes. For optimal performance, the material's length-to-width ratio should exceed 50%.

Whether for high-volume production or customized packaging, the Inphic AI Intelligent Packaging Alignment Machine delivers exceptional performance, enabling brands to excel in a competitive market.

AI-Powered High-Precision Inspection Equipped with multiple high-precision sensors and advanced AI inspection algorithms, this machine conducts posture detection and weight measurement on each product, removing defective items (such as horizontal bags, connected bags, or underweight products) to ensure consistent final product quality.

-

Accuracy Rate: Up to 99.9%, enhancing your brand’s quality image.

Key Features:

- Configured with four active orientation modules for consistent lengthwise material output.

- Customizable based on material width; material length-to-width ratio must exceed 50%.