INPHIC

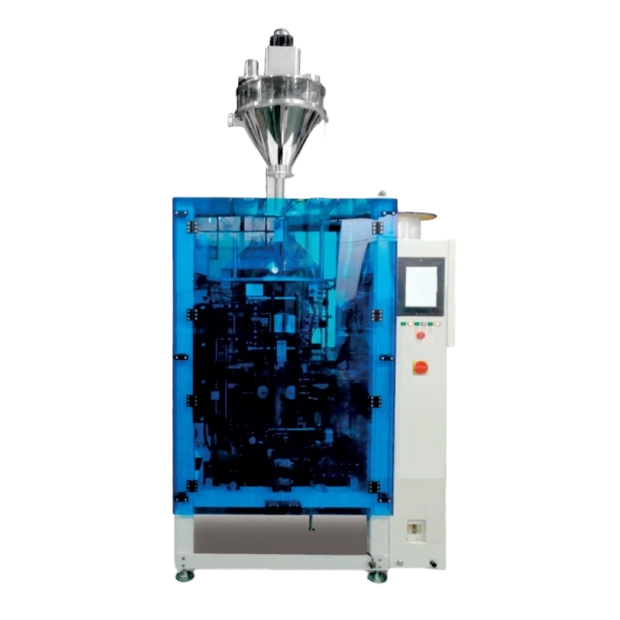

Since its founding in 2007, 友創 Information Co., Ltd. has been at the forefront of innovative design for food service and processing equipment. Through our in-house brand, INPHIC, we are committed to delivering professional and customized equipment solutions to the global hospitality, food service, and food processing industries. We focus not only on enhancing front-end equipment for food service environments and automating back-end production systems but also provide comprehensive intelligent packaging line machinery for industrial clients. Our solutions support food processing partners with stable, high-efficiency production equipment, addressing instability caused by workforce fluctuations and advancing next-generation automation in production.

AI-Driven High-Precision Inspection

The machine is equipped with multiple high-precision sensors and advanced AI detection algorithms, enabling posture detection and weight measurement for each packaged product. It automatically rejects defective items (such as misaligned bags, connected bags, or products that do not meet weight specifications), ensuring consistency in the final product quality. With an accuracy rate as high as 99.9%, it reinforces your brand's reputation.

Industry Application Scope

AI Smart Packaging Line OrganizerThe application scope is very extensive, covering almost all industries involved in soft bag packaging. Here are a few typical application scenarios

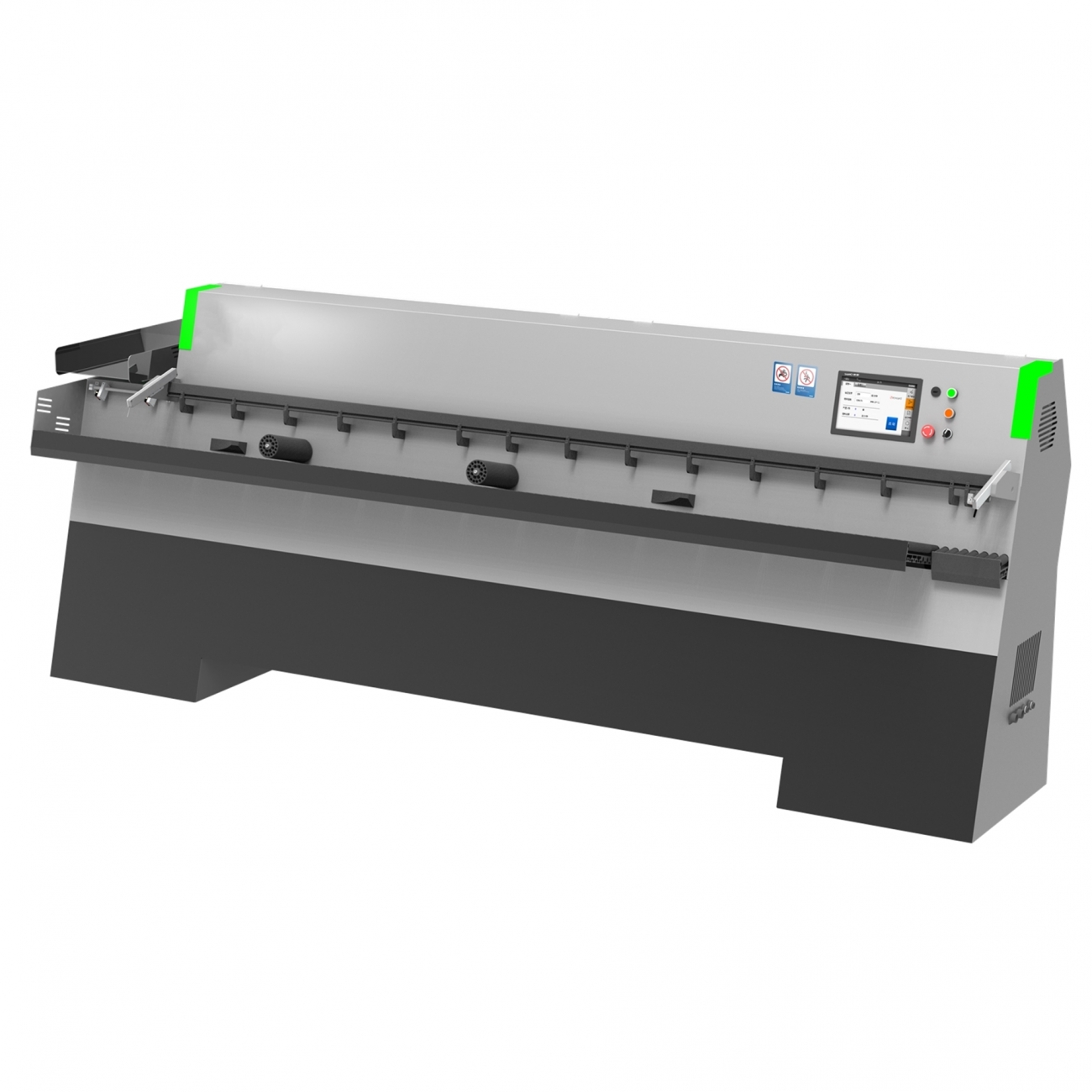

● Food Processing Industry Applicable to the efficient sorting and packaging of various soft bag foods such as snacks, frozen foods, and ready-to-eat meals, greatly enhancing the automation level of the production line.

● Pharmaceutical manufacturing industry:For soft bag packaged pharmaceuticals, such as powder packaging and soft capsule bags, the AI intelligent sorting machine can achieve precise and efficient production processes while ensuring a high consistency in drug quality.

● Daily chemical industry:For example, packaging for laundry detergent and soft bags for skincare products, the equipment can quickly identify and organize soft bag products of different specifications, enhancing the flexibility of the production line.

Case Analysis Witness Our Successful Results

Here are several case analyses of successful implementations of AI intelligent sorting machines, showcasing the equipment's outstanding performance in various application environments. Let's assume a medium-sized manufacturing company introduced an automated assembly machine.

●Labor cost savings:

Originally, 10 workers were needed, each with a monthly salary of 40,000 NT dollars, totaling 400,000 NT dollars per month. After purchasing the machine, only 2 operators are required, totaling 80,000 NT dollars per month.

Saves 320,000 NT dollars monthly.

●Production efficiency improvement.:

The original monthly production was 10,000 units, and after automation, it increased to 20,000 units, resulting in a 100% increase in output.

● Quality Improvement: